| Course | Cycle | Course | Cycle |

|---|---|---|---|

| IATF 16949 :2016 QMS understanding and implementation | 2 | VW supplier competency evaluation criteria-Formel-Q | 2 |

| APQP –Basic class | 1 | Product safety responsibility and control of D parts | 1 |

| PPAP-Basic class | 1 | VW project management-QPNI | 2 |

| APQP &PPAP Application ability improvement | 2 | BIQS | 3 |

| D&PFMEA –Basic class | 2 | QSB+ | 3 |

| D&PFMEA Application ability improvement | 3 | GP12 | 1 |

| DFMEA | 1 | Q1 | 3 |

| PFMEA | 1 | ASES-Nissan customer requirements introduction | 2 |

| SPC –Basic calss | 1 | SPC- Application ability improvement | 2 |

| MSA –Basic class | 1 | MSA- Application ability improvement | 2 |

| Practice of core tools of quality management in automotive industry | 5 | Quality management in automotive product development | 1 |

| Introduction to international material data system IMDS for automotive industry | 1 |

| Course | Cycle | Course | Cycle |

|---|---|---|---|

| Maturity level assurance of Germany automotive industry(MLA) (MLA) | 2 | CQI-8 Layer process audit | 1 |

| Robust production process RPP | 2 | CQI-9 Heat treatment system audit | 2 |

| VDA6.1Internal audit | 3 | CQI-10 Effective problem solving | 1 |

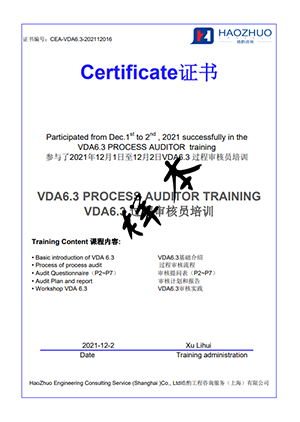

| VDA6.3 Process audit | 3 | CQI-11 Plating system audit | 2 |

| VDA6.4 Production equipment quality management audit | 3 | CQI-12 Coating system audit | 2 |

| VDA6.5 Product audit | 1 | CQI-14 Automotive warranty evaluation | 2 |

| VDA6.7 Production equipment process audit | 2 | CQI-15 Welding system audit | 2 |

| VDA 5 Measurement process capability | 1 | CQI-17 Soldering system audit | 2 |

| VDA19 Cleanliness | 2 | CQI-18 Effective error proofing Guide | 2 |

| CQI-23 Injection system audit | 2 | ||

| CQI-27 Casting system audit | 2 |

| Course | Cycle | Course | Cycle |

|---|---|---|---|

| Qualification training for electric vehicle practitioners(Germany IE8686) | 2 | Seven old tools for quality improvement | 1 |

| Electric vehicle high voltage system training | 2 | Seven new quality improvement tools | 1 |

| Training of charging pile installation personnel | 3 | Basic quality tool training for front-line team leaders | 1 |

| Power battery training | 3 | Application of statistical sampling in quality control | 1 |

| Used car technology assessment training | 2 | 8D problem solving | 1 |

| After sales technical training (in cooperation with OEM, for electric vehicles) | 2 | TRIZ-Theory and practice of innovative problem solving | 1 |

| After sales comprehensive service management training | 1 | QFD-Quality function deploy | 1 |

| Workshop efficiency improvement | 1 | DOE Design of experiment | 3 |

| FTA Failure tree analysis | 2 | Reliability engineering | 2 |

| Tolerance analysis | 1 | GD/T Geometric Dimensioning & Tolerancing | 2 |

| POKA YOKE | 1 | Quality cost control | 1 |

| pplication of Minitab in quality management | 1 |

| Course | Cycle | Course | Cycle |

|---|---|---|---|

| 5S and visual management | 2 | Lean Kanban and Andon | 2 |

| Lean problem solving | 2 | Fast die change-SMED | 2 |

| Effectively eliminate waste | 2 | POKE-YOKE | 2 |

| Lean thought introduction | 2 | Lean automation production | 2 |

| Improvement of lean production management skills | 2 | Material planning and inventory control | 2 |

| Continuous improvement workshop | 2 | Production planning and scheduling | 2 |

| Lean balanced production | 2 | Production planning and material control | 2 |

| Kanban pull production system | 2 | Warehouse management and inventory control | 2 |

| Create continuous production flow | 2 | How to realize zero inventory plan | 2 |

| Lean just in time production-JIT | 2 | How to effectively reduce logistics costs | 2 |

| Lean value stream analysis | 2 | Lean logistics -- let materials flow | 2 |

| Lean finance and cost management | 2 | Flexible production planning and scheduling | 2 |

| Lean target management | 2 | Supply chain lean value flow analysis | 2 |

| Lean high-level core concept | 2 | MMOG/LE Principle and Implementation | 2 |

| Plant equipment maintenance and TPM | 2 | Overall equipment efficiency OEE | 2 |

| Standardized operation -- the cornerstone of improvement | 2 |